A revolution in measurement technology

There's exciting news in the world of metrology and quality control! Our brand new ATX probe is here and promises to transform the entire field of component inspection. But why did we develop it?

Our old probe presented numerous challenges. Installation in the fixture was often a laborious process. Guide sleeves with inaccurate dimensions, a small probe with too much play and problematic threads on the probe carriers - all these factors cost time and nerves. The assembly problems reached their peak with the introduction of the new generation of Agilent Nano-Vtep probes, which were simply difficult to handle and did not hold the probe discs reliably. This was a significant problem not only for us, but also for our customers. After 18 years, it was time to make an improvement.

But what are the advantages and disadvantages of our new ATX probe?

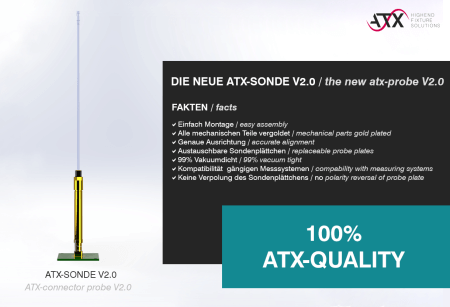

Simple installation: Thanks to high-quality and precise mechanical components, installation is child's play.

All mechanical parts gold-plated: For optimum conductivity and durability.

Precise alignment: Thanks to minimal radial tolerances, precise alignment with the component to be tested is guaranteed.

Replaceable probe discs: Easy replacement and quick maintenance are possible.

99% Vacuum-tight: Without the use of seals, thanks to high dimensional stability.

Compatibility: The ATX probe is compatible with all common measuring systems such as Keysight-Nano-V-Tep, SPEA, Teradyne-OFM, Teradyne-Frame-Scan, Reinhardt, Digitaltest-Opens-Check and Aeroflex.

No polarity reversal of the probe disc possible: For reliable measurement.

The development of the ATX probe is a major step forward in taking our quality inspection and component analysis to the next level. We are convinced that this innovation not only optimises our own processes, but also helps to increase efficiency and accuracy throughout the industry. If you recognise the potential of this technology, don't hesitate to contact us to find out more.