TRAINING FOR

CUTTING MACHINE OPERATOR (M|W|D)

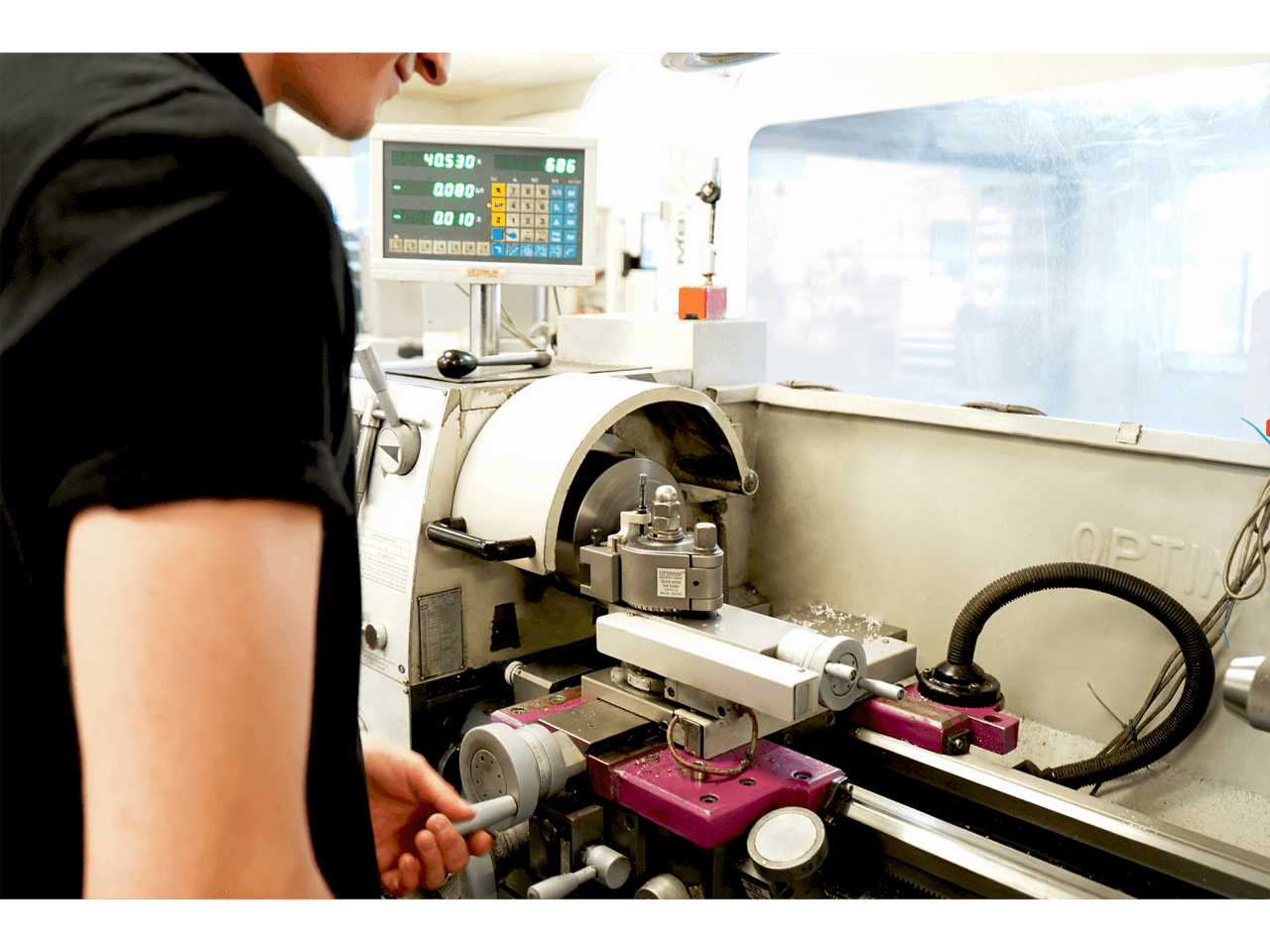

You produce precision components made of metal and plastic according to technical documentation using machining processes such as turning, milling, welding or grinding. Mechanical and computer-assisted machines are available to you for this purpose. You create programmes for these machines and assemble, maintain and repair them. You set up milling machines and lathes, including the tools, and monitor the production processes. Finally, you check the workpieces for quality and dimensional accuracy.

YOUR TASKS

- Manual or machine processing of metal workpieces with the aid of machining processes such as turning, milling and grinding.

- Assembling individual components into assemblies

- Independent configuration and maintenance of machine tools

- Checking the machine run and checking the quality and dimensional accuracy of the manufactured components

YOUR PROPERTIES

- Technically versed

- Craftsmanship

- Affinity for mathematical and physical understanding

- Precise work

- Spatial imagination

- High comprehension

FACTS

TYPE OF TRAINING:

DUAL

TRAINING PERIOD:

3.5 YEARS

VOCATIONAL SCHOOL:

VOCATIONAL SCHOOLS LANDSBERG AM LECH

SCHOOL-LEAVING CERTIFICATE:

GOOD INTERMEDIATE MATURITY OR

M-TWEIG

Interest aroused?

Then choose an apprenticeship as a cutting machine operator at ATX Hardware.

Our goal is to train you optimally for the CNC area and to teach you all common process techniques.

PRECISION AND QUALITY THROUGH TRAINING IN FIXTURE CONSTRUCTION.

APPLY NOW AND SECURE YOUR TRAINING PLACE for 2026